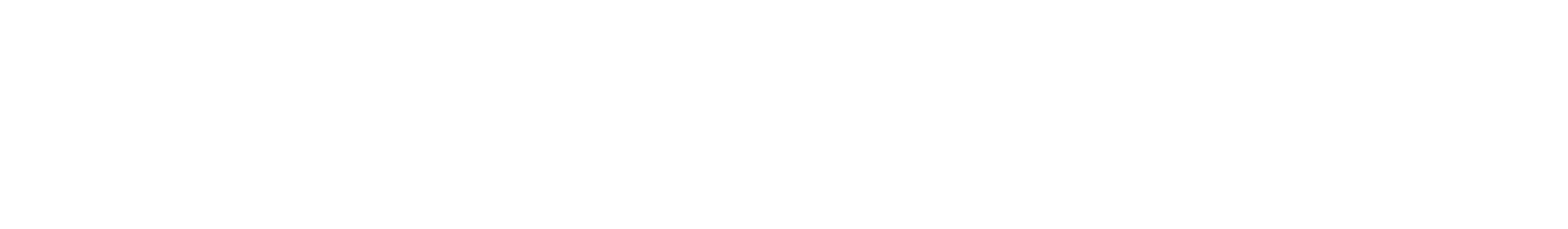

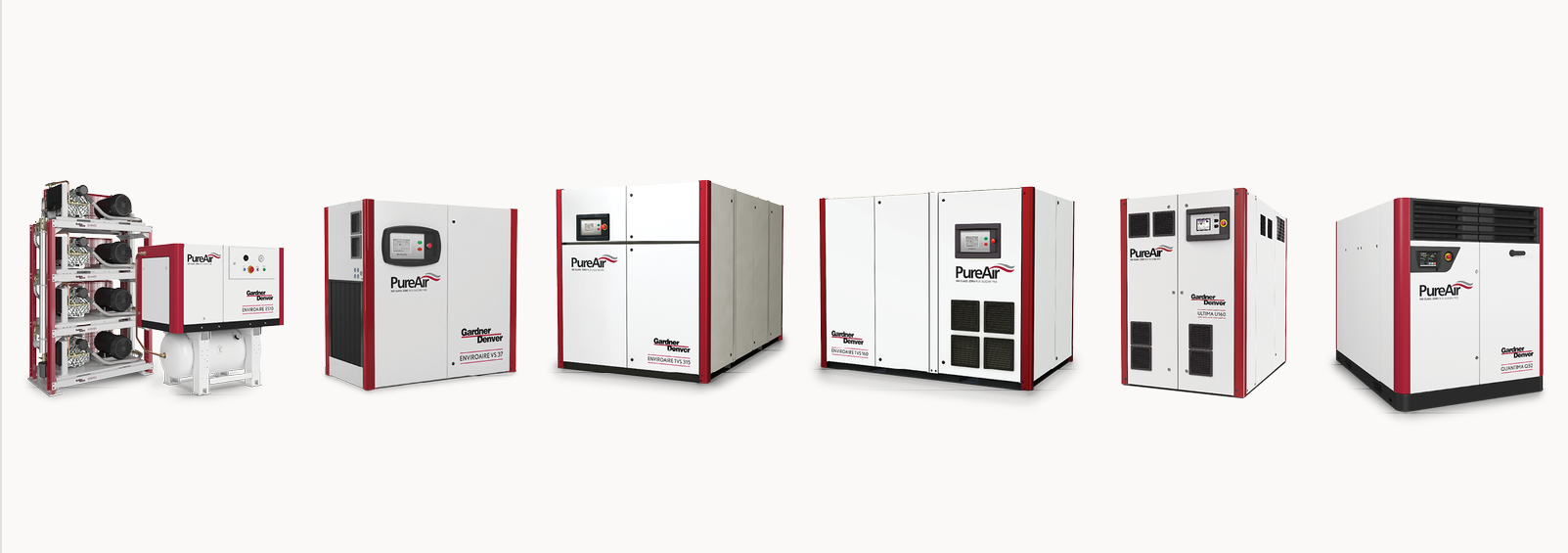

Discover our

compressor solutions

Here, you will find a comprehensive range of compressed air products and services to meet your unique needs. Our team is dedicated to providing complete solutions that are tailored to your specific requirements, whether you need a new system or want to improve your existing one. We offer a wide range of energy-saving incentive applications, parts and service assessments, and long-term care packages to ensure that your system runs smoothly and efficiently. Additionally, we offer emergency services to address any unexpected disruptions. Browse our products and services to and the perfect fit for your compressed air needs.

Check out our catalogue below

- Largest range of product portfolio form any rotating equipment supplier in the world

- Industry leading warranty programs with easy to understand terms and no difficult compliance requirements

- Product reliability and reputation for high quality that was established back in 1859

- Worldwide distribution support with GTA Compressor Solutions the largest Canadian dealer

Diverse product offering with scroll, water injected rotary, two stage oil free rotary and centrifugal designs

Industry leading warranty programs with easy to understand terms and no difficult compliance requirements

Product reliability and reputation for high quality that was established back in 1859

Worldwide distribution support with GTA Compressor Solutions the largest Canadian dealer

Comprehensive range of refrigerated, membrane and desiccant air dryer technology, filtration, and breathing air products

High quality reliable product portfolio that dates back to the 1859 era

Worldwide support on all products with GTA Compressor Solutions the largest Canadian GD representative

GTA Compressors have an in-house dryer certified technician to service or repair dryers without the need for sub-contracting

System matched products that work in conjunction with GD compressors or any other manufacturers compressor models

Purity levels obtainable down to 99.9998% purity

Worldwide supported product line

Large and fast payback compared to N2 rental systems typically used in this market

In house N2 expert who services and repairs all makes of N2 equipment

Unique media that eliminates carbon bag technology and makes disposal easy to effect

Keeps oil content into drains and sewers to less than 15ppm to comply with Ontario legislation

Service time and cost 30% less than older carbon bag technology

Will not leak or spill oil over the plant room floor as older technology units regularly do

All models and service ekits immediately available from stock

Large range from 20-10,000 gallon

Standard 100psig to high pressure custom tanks available

ASME certification

Complete with dressing kits

All tanks are mild steel meet Canadian legislation reference materials and certification

Standard or customized control technologies to manage and advise on compressor system warnings, alarms or shutdowns

Unique in house monitoring system that advises clients second by second views of their compressor status and any issue that are about to happen or have alarmed.

Easy to install

No risk of ‘hacking’ or remote intervention

Save clients thousands of dollars a year on wasted energy savings since compressor unload or idle time is correctly monitored and controlled.

Full range of local BA kits and equipment to use at point of application

BA skid packages available to handle medium and high flow duties to purify air in critcal applications for multiple users

Equipment meets Canadian BA legislation

All air testing is by a third party accredited air putrity laboratory

GTA have a combined experience in this field which amougst staff exceeds 150 years.

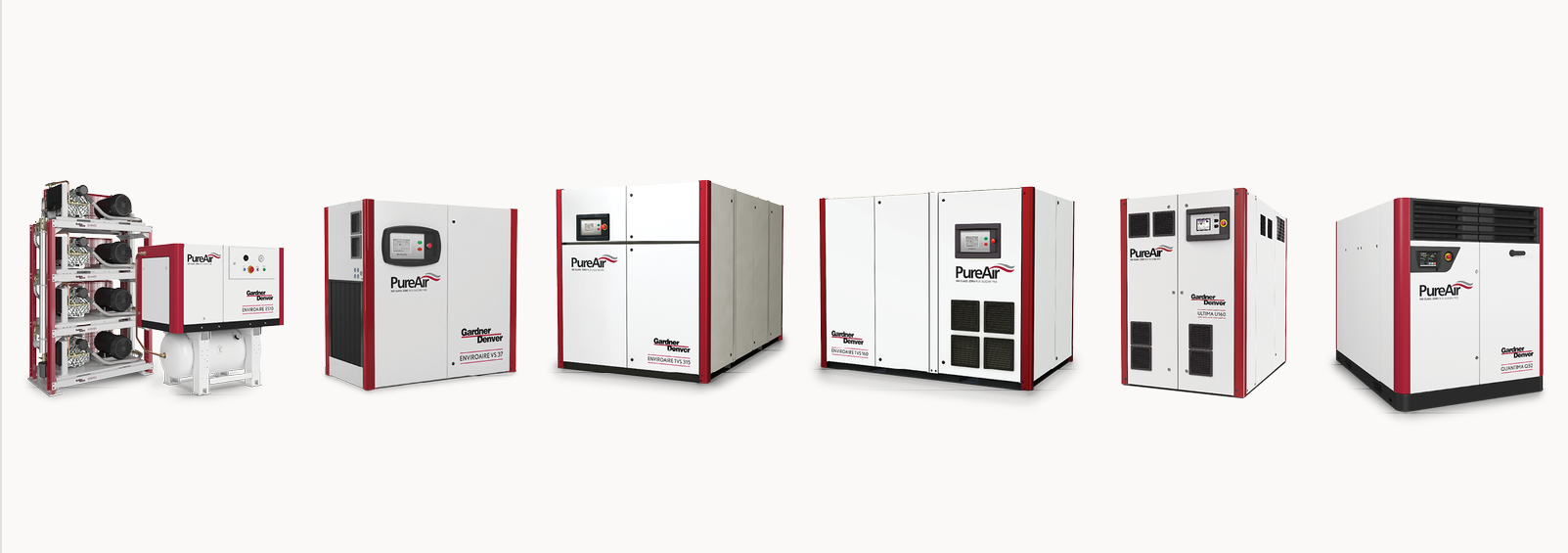

img

GD products of this design used by many marine and defence Navel frigates and submarines all across the world

Reputation and product portfolio based on reliability, and fast service support

250-600 psi applications in air and water cooled offerings

Service support for parts or technicians via GTA Compressor Solutions across Canada

Applications for air start, military, lazer cutting etc are common.

Reference points from long standing users all across the world

Customization available to mount gauges in certain areas, move inlet/outlet ports etc available to match site requirements

img

GD products have served these critical markets for over 100 years

Reputation and product portfolio based on reliabilty and fast service support

250-600 psi applications in air and water cooled offerings

Service support for parts or technicians via GTA Compressor Solutions across Canada

Appliactions for air start, military, lazer cutting, PET bottle blowing etc are common.

Reference points from long standing users all across the world

img

Market leader in BA compressor technology

Large portfolio of Hp compressors 5000-6000 psi with fill stations and accessory products

Relaibaility and ease of parts / service supply critical in BA applications

GTA are the largest mako distributor in Canada based in Burlington ON

Air testing by a third part laboratory every six months will keep the system BA complient.

Check out our catalogue below

- Largest range of product portfolio form any rotating equipment supplier in the world

- Industry leading warranty programs with easy to understand terms and no difficult compliance requirements

- Product reliability and reputation for high quality that was established back in 1859

- Worldwide distribution support with GTA Compressor Solutions the largest Canadian dealer

Diverse product offering with scroll, water injected rotary, two stage oil free rotary and centrifugal designs

Industry leading warranty programs with easy to understand terms and no difficult compliance requirements

Product reliability and reputation for high quality that was established back in 1859

Worldwide distribution support with GTA Compressor Solutions the largest Canadian dealer

- Comprehensive range of refrigerated, membrane and desiccant air dryer technology, filtration, and breathing air products

High quality reliable product portfolio that dates back to the 1859 era

Worldwide support on all products with GTA Compressor Solutions the largest Canadian GD representative

GTA Compressors have an in-house dryer certified technician to service or repair dryers without the need for sub-contracting

System matched products that work in conjunction with GD compressors or any other manufacturers compressor models

Purity levels obtainable down to 99.9998% purity

Worldwide supported product line

Large and fast payback compared to N2 rental systems typically used in this market

In house N2 expert who services and repairs all makes of N2 equipment

Unique media that eliminates carbon bag technology and makes disposal easy to effect

Keeps oil content into drains and sewers to less than 15ppm to comply with Ontario legislation

Service time and cost 30% less than older carbon bag technology

Will not leak or spill oil over the plant room floor as older technology units regularly do

All models and service ekits immediately available from stock

Large range from 20-10,000 gallon

Standard 100psig to high pressure custom tanks available

ASME certification

Complete with dressing kits

All tanks are mild steel meet Canadian legislation reference materials and certification

Standard or customized control technologies to manage and advise on compressor system warnings, alarms or shutdowns

Unique in house monitoring system that advises clients second by second views of their compressor status and any issue that are about to happen or have alarmed.

Easy to install

No risk of ‘hacking’ or remote intervention

Save clients thousands of dollars a year on wasted energy savings since compressor unload or idle time is correctly monitored and controlled.

Full range of local BA kits and equipment to use at point of application

BA skid packages available to handle medium and high flow duties to purify air in critcal applications for multiple users

Equipment meets Canadian BA legislation

All air testing is by a third party accredited air putrity laboratory

GTA have a combined experience in this field which amougst staff exceeds 150 years.

img

GD products of this design used by many marine and defence Navel frigates and submarines all across the world

Reputation and product portfolio based on reliability, and fast service support

250-600 psi applications in air and water cooled offerings

Service support for parts or technicians via GTA Compressor Solutions across Canada

Applications for air start, military, lazer cutting etc are common.

Reference points from long standing users all across the world

Customization available to mount gauges in certain areas, move inlet/outlet ports etc available to match site requirements

img

GD products have served these critical markets for over 100 years

Reputation and product portfolio based on reliabilty and fast service support

250-600 psi applications in air and water cooled offerings

Service support for parts or technicians via GTA Compressor Solutions across Canada

Appliactions for air start, military, lazer cutting, PET bottle blowing etc are common.

Reference points from long standing users all across the world

img

Market leader in BA compressor technology

Large portfolio of Hp compressors 5000-6000 psi with fill stations and accessory products

Relaibaility and ease of parts / service supply critical in BA applications

GTA are the largest mako distributor in Canada based in Burlington ON

Air testing by a third part laboratory every six months will keep the system BA complient.

Our major clients